Online Monitoring System For Knitting

Monitor Knitting Performance. Enhance Productivity

Classic Loom Data Online Data Acquistion System for knitting facilitates continuous monitoring of each machine. Various parameters like weight and the length of the knitted fabric can be had at the click of a button. The knitting performance can be significantly enhanced.

The Classic Loom Data system helps in seamless running of the knitting operation and contributes to better productivity. Trusted by leading mills worldwide, the Classic Loom Data Online Data Acquistion System for Knitting is designed to deliver results, consistently. By taking the appropriate steps the efficiency of the Shed / Operator can be increased immediately.

Classic Loom Data at the heart of productivity

When it comes to providing total solutions for textile automation, Classic Loom Data is in a league on its own. Incorporating innovative technologies Classic Loom Data manufactures Online Data Acquistion Systems for Spinning, Weaving, Knitting and Fabric Inspection. For the past one and a half decades, the company has quietly established its reputation as a trusted partner in progress for customers across India,All over india. Strong focus on R&D and a clear perception of customer requirements have contributed to Classic Loom Data’s ability to provide customized solutions to help improve productivity and quality.

Classic Loom Data’s facilities are top-of-the-line. A dedicated team of engineers backed by highly experienced people at the helm ensure that every product from their stable delivers results.

Benefits of Online Data Acquisition System

- Integrated information solutions covering all types of Machines

- Viewing of Production, Stoppage, Efficiency & Speed Information on the machine

- Various reports on Production, Stoppage, Efficiency, etc.,

- Order Planning and Yarn consumption reports

- Comparison reports on Machines, Operators, Shifts, etc.,

- Performance reports forTop Level Management

- Snap Study on Running / Stopped machines

- Exception reports on Efficiency, Production & Stoppage limits

- Easy identification of Efficiency of the machines in different colours

- Various Graphical reports

- Efficiency Trend Graph for a Shift, Day

- Modular design & hence easy to add new machines

- ERP Interface / Excel Transfer

Data Collection Unit on each machine

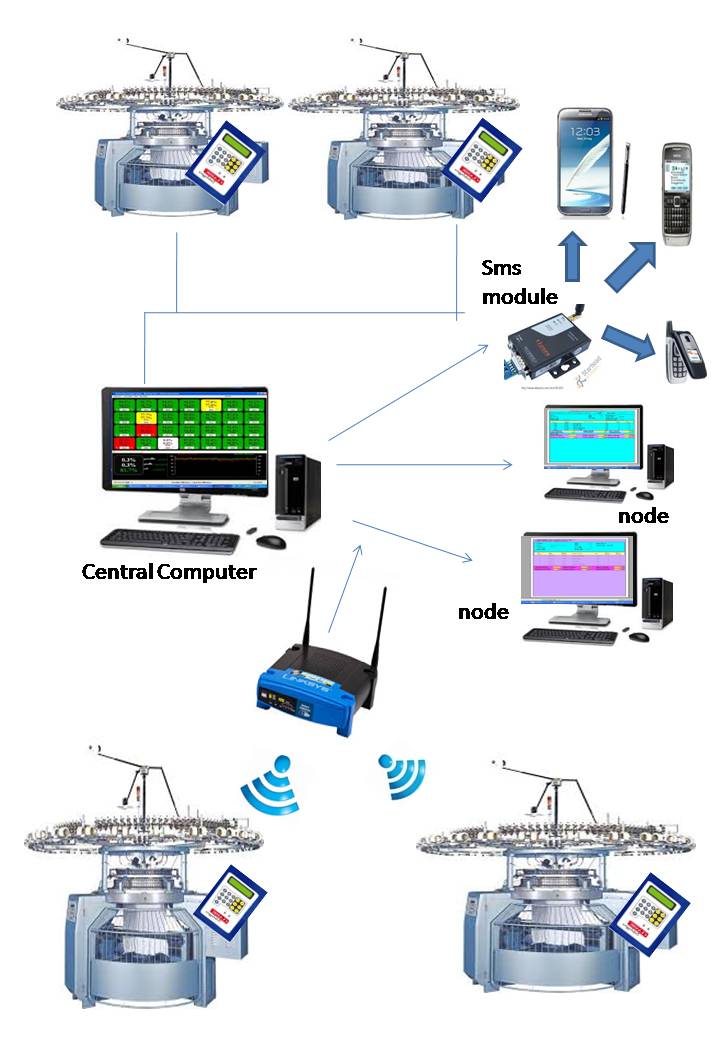

The Machine Terminal comes with an in-built micro controller, a user friendly keyboard and display for ease of operations. The data collected from the machines is transferred to a central computer Online (wired or wireless).

Software

Software is installed on the Central Computer collects the data from the Data Collection Unit

instead of Machine Terminal through the Data Communication unit and generates various reports.

It has the facility to transfer the data to an ERP system / EXCEL.

The software can be installed on various Nodes across the plant.

Configuration

Classic Loom Data SMS/Mail Alerts ( Optional )

Classic Loom Data SMS/Mail Module can send alerts automatically on production, efficiency, stoppage, minutes per stop, breaks per hour and other required information as and when it reaches a preset value of customer’s choice.

Classic Loom Data SMS Module comes with a hardware for installing SIM Card and a software to program the mobile phone numbers, alerts and the frequency of alerts.

- End of Shift and End of Day data alerts.

- Various alerts at selected intervals (eg. Every hour)

- SMS can be sent to various mobile numbers of customer’s choice

The large display score board displays the performance efficiency of the shed and helps to motivate floor level workers. It offers a psychological boost to the workers to optimise their performance level. Score Board helps workers to assess their own performance and score better in their subsequent operations.