Online Fabric Inspection System

Introducing a revolutionary new technology for fabric inspection

Classic Loom Data presents yet another innovative technology for the textile industry – Online Fabric Inspection System. Manual inspection and recording of defect codes will never be the same again.

Fabric Inspection – The Conventional Way

The operator manually records the defect code and the length at which the defect has occurred in a pre-printed stationery for further analysis. This is a cumbersome process resulting in inaccurate storage / analysis and thereby affecting the quality of end product.

Fabric Inspection – The Classic Loom Data Way

The Classic Loom Data Fabric Inspection Terminal (FIT) is equipped with a state of the art micro controller. It is interfaced with a shaft encoder for accurate measurement of the fabric length. The operator enters the defect code and the depth of the defect using the keyboard. The system automatically records the length at which the defect occurred. Operator can enter inputs such as code, fabric type etc at the beginning of the inspection. The input parameters can be tailored to suit the specific requirements of the mills. After inspection, a print out can be taken or the data can be transferred to ERP. The data is stored in an SQL Server/Oracle database for further analysis. A defect map is generated for each roll and fabric can be graded based on the defects.

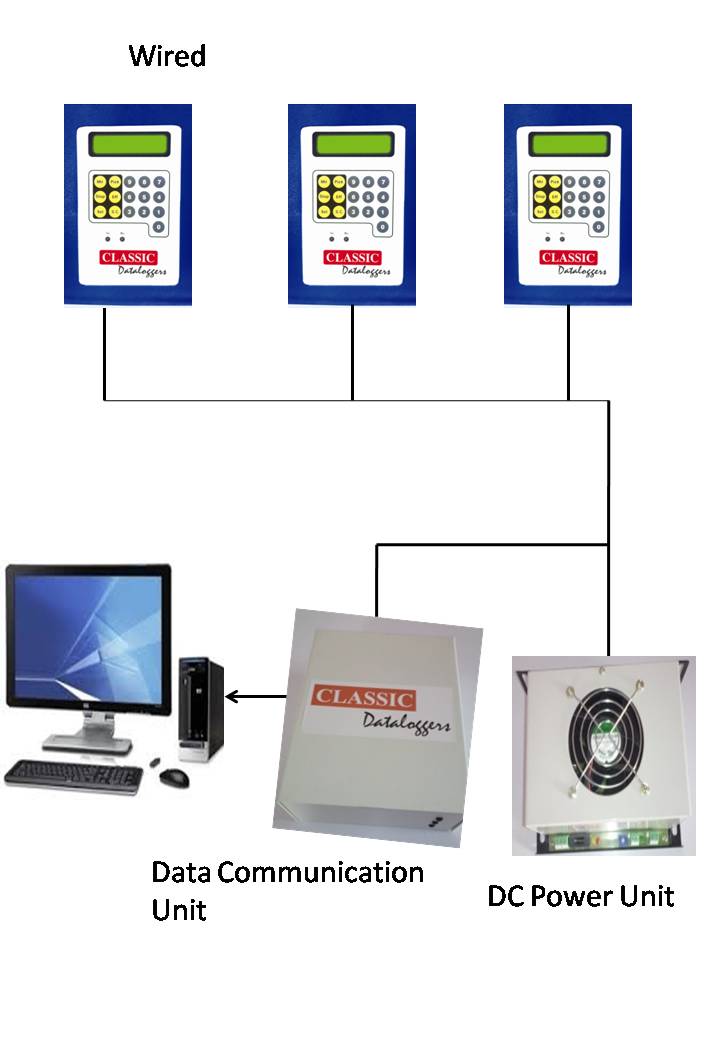

A number of such Fabric Inspection Terminals (FIT) can be connected to a central computer.

System Configuration

Classic Loom Data Fabric Inspection Terminal comes with the following hardware & software:

- Fabric Inspection Terminal- FIT( Wired or Wireless Model) ( Keypad or Touch Screen Model)

- Shaft Encoder, Power Multiplexer & Basic Software

- The Fabric Inspection Terminal is a micro controller based unit with inbuilt memory, digital and analog interface.

- It has predominant keys and numerical keys to enter the defect code and the points. The shaft encoder is connected to the terminal to measure the meters inspected.

How does it work?

- The Standard Parameters for the fabric to be inspected (Roll Number, Quality, Loom Number, Inspector ID, Fabric width, Selvedge width,

Roll Doff Date, etc.,) are entered at the start of inspection - Collects the fabric length automatically through the Shaft Encoder whenever the fabric moves on the table

- Displays the Inspected meters.

- Operator / Inspector to enter the Defect Codes with Points as when he sees a Defect on the fabric

- In case of any Reverse Running of the Machine, the FIT will take care of the same.

- The Defect Codes entered will be stored in the Terminal and in turn transferred to the Central Computer

Basic Software

The Online Fabric Inspection software running on the computer collects the data from the FIT and arranges in well-structured reports, which can be easily interpreted. GUI nature of the software eliminates complicated keystrokes and codes. Option for transferring the data to Microsoft Excel, ERP is available.

Why Classic Loom Data:

We have over two decades of experience in helping the textile industry across the globe in solving their monitoring and inspection problems. As specialists in textile technology, we offer you a comprehensive range of innovative products and services including design, installation and maintenance.