Data Collector With RFID Reader and LCD Display

Model No. : CLD-01 K

This CLD-01 K Model Data Collection Unit comes with an in-built Microcontroller & WiFi Connectivity , a user friendly RFID Reader and display for ease of operations. The Data Collection Unit collect Datas from the any type machines( Looms, Ring Frame, Carding , Drawing, Knitting, ...etc) and transferred to a central computer via WiFi Router.

RFID Reader can be used for Assign Stop Codes / Operators / Fitter / Supervisor / Stop Codes / Quality / .. Etc

Online Production Monitoring System

Monitor Performance. Enhance Productivity

Productivity is assured by the continuous performance of every single Machines/Looms in the Industries / Mills. Unwanted stoppages can throw a spanner in the works and drastically impact production schedules. That is why it is imperative to invest in Online Production Monitoring Systems. Trusted by leading Industires/Mills worldwide, the CLD Online Data Acquisition systems deliver results.

CLD Online Data Acquisition System facilitates continuous monitoring of each machine individually and collectively. The data is processed and useful reports generated help in the seamless running of all operations. All contributing to better productivity which, of course, translates into higher profits

Information at the click of a button

CLD Online Data Acquisition System is feature rich and provides integrated information at a click. The software for the Online system is in Visual Basic / Dot Net with SQL server or Oracle as backend.

Benefits of Data Acquisition System

- Integrated information solutions covering all types of LOOMS

- Combination of loom types on one computer

- Viewing of Production, Stoppage, Efficiency & Speed information on the machine

- Reason for long stop can be entered on the machine

- User friendly menu driven software on the computer

- Various reports on Production, Stoppage, Efficiency, etc

- Beam Runout Reports for Beam Planning

- Comparison reports on Machines, Weavers, Shifts, etc.,

- Performance reports for Top Level Management

- Snap Study on Running / Stopped Looms

- Exception reports on Efficiency, Production & Stoppage limits

- Weaver Planning

- Easy identification of Efficiency of the machines in different colours

- Various Graphical reports in Line graph, Bar graph, 3D Pie Chart, Scattered graph

- Efficiency Trend Graph of a Shift, Day

- Modular design & hence easy to add new machines

- Standard Computer & Printer

- Standalone or Network operation

- ERP Interface / Excel Transfer

- Optional – Score Board to Display the Efficiency of the shed

- Optional – SMS Alerts Module

- Optional – Reports by e-mail

Software

The computer, on which the Online Data Acquisition system software is installed, collects the data from the Data Collection Unit instead of Machine Terminal through the Data Communication Unit and generates various reports. The software acquires the data from the looms and arranges in well-structured reports, which can be easily interpreted. The reports can be called through the Menu Driven User Friendly Software. GUI nature of the software eliminates the complicated keystrokes and codes. It has the facility to transfer the data to an ERP system. The software can be installed on various nodes across the plant.

Report Options

- > Production Report

- > Breakage Report

- > Efficiency Analysis Report

- > Beam Planning Report

- > Overall Management Performance Report

- > Roll Doff Report

- > Comparison Report

- > Monthly Efficiency / Stoppage Analysis Report

- >> Current Shift

- >> Every One Hour

- >> Any Finished Shift

- >> One Day Report

- >> From To Date

- >>> Loom

- >>> Quality/ Sort / Style wise

- >>> Beamwise

- >>> Operator / Operator Group

- >>> Fitter

- >>> Supervisor

- >>> Machine Type / Shed Wise

- >>> Order Number

- >>> Warp / Weft/Sizing Supplier

Report Types

Period

Group By

The above reports can be called on the screen or on the printer. The user can get all the information at their fingertips. By taking the appropriate steps the efficiency of the Shed / Weaver can be increased immediately.

CLD at the heart of productivity

When it comes to providing total solutions for textile automation, CLD is in a league on its own. Incorporating innovative technologies CLD manufactures Online Data Acquisition Systems for Spinning, Weaving, Knitting and Fabric Inspection System. For the past one and a half decades, the company has quietly established its reputation as a trusted partner in progress for customers across India, All over world. Strong focus on R&D and a clear perception of customer requirements have contributed to CLD’s ability to provide customized solutions to help improve productivity and quality.

CLD's facilities are top-of-the-line. A dedicated team of engineers backed by highly experienced people at the helm ensure that every product from their stable delivers results.

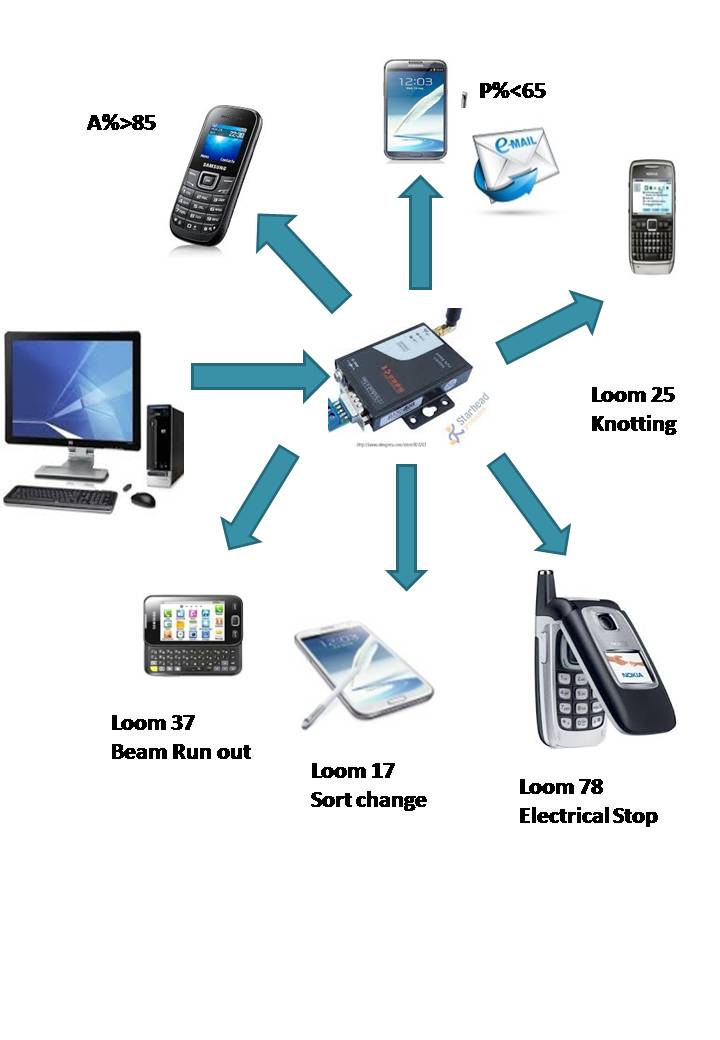

CLD SMS/Mail Alerts (Optional)

Monitoring the performance of your mill has never been this easy. CLD will keep you connected wherever you’re in the world. CLD SMS/Mail Alerts Module will send you alerts automatically on Production, Efficiency, Stoppage, Minutes per Stop, Breaks per Hour and other required information as and when it reaches a preset value of your choice.

Advantage:

Put up a Score Board. Step up productivity (Optional)

CLD also offers you Score Board as an optional product available in two sizes. The large display score board displays the performance efficiency of the shed and helps to motivate floor level workers. In other words, Score Board can be used as a performance enhancing tool by letting the workers know for sure where they stand in terms of overall performance. It offers a psychological boost to the workers to optimize their performance level. Score Board helps workers to assess their own performance and score better in their subsequent operations.